All across perforating

Soenen is the leading manufacturer of high-performance perforating presses. Our machines provide an extremely high feeding accuracy, resulting in excellent productivity and perfectly perforated sheets. Our fastest presses reach speeds up to 800SPM (strokes per minute) and have high feeding accuracies of 0.02mm. The result is high productivity and - most importantly - perfect perforated sheet.

Hole dimensions can vary from 0.6mm to 8mm or more and the press force can be as high as is 6,000 kN or 600 Ton. From thick carbon steel to thin and fragile aluminum sheets, from narrow width to large format sheets, over the years we have gathered all the necessary skills to build any kind of press for any kind of material.

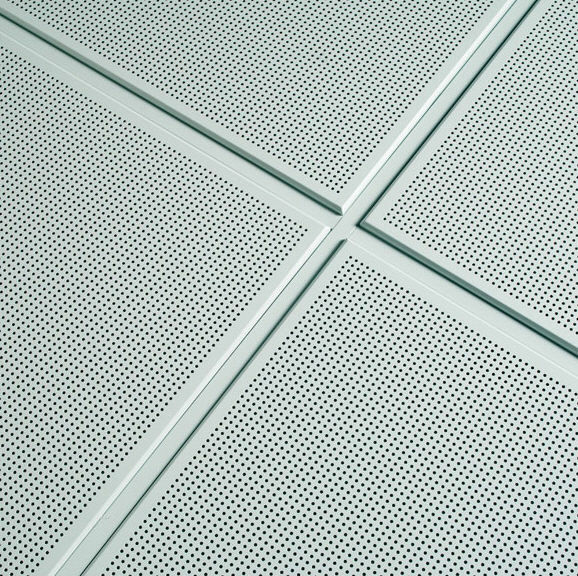

At first glance, the thin perforated metal sheet in a microwave or ceiling tile might seem easy to make, but in reality it requires a rather complex production process that combines high speeds and extreme accuracy.

A wide variety perforated coil or perforated metal sheets are used in construction, industry, and consumer goods. Just think of the perforated metal that is used as sound barriers. These massive boards absorb and filter noise from railways, roads, construction sites and airports. Other applications can be filters and sieves obtained by micro perforation which are in high demand by the food and pharmaceutical industries. Decorative perforation in stainless steel or aluminum are other examples of the application diversity of perforated metal.

Please contact your local representative for more information. More videos about our perforating equipment you can find on our YouTube playlist. Do not forget subscribe to stay updated about our latest developments.

Your project soon?

Contact us.

-

Turn-key

solutions -

Expert in

sheet metal processing -

Member of the

Valtech Group -

Contact us

regarding your project