Stacking solutions

The method of stacking a transformer core is defined by the individual reality within each transformer manufacturing company. The guarantee of a return of investment is largely defined by finding the best balance between stacking automation and the labor required to complete the transformer assembly.

Soenen therefore assists each of its customers with in-depth advice on what is possible and what is reasonable. Defining the correct stacking system allows us to align all cutting activities accurately prior to stacking at the best possible cost.

E-Stacking

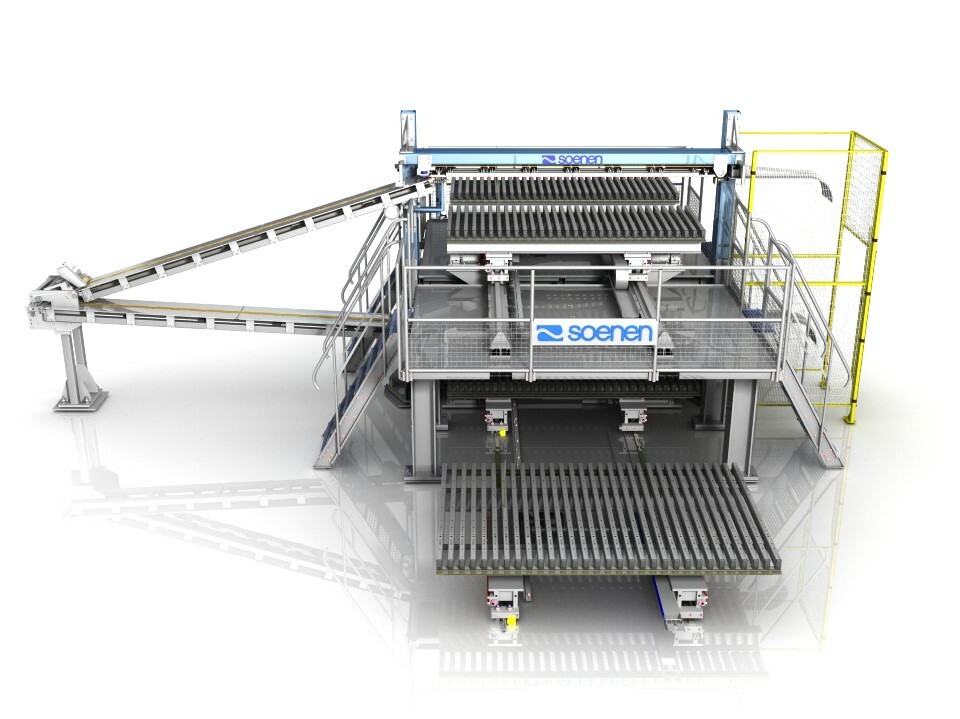

In order to make the manufacturing of a transformer more efficient, flexible and accurate we developed two different E-stacking concepts that will revolutionize the transformer market: the Soenen in- and off-line E-stacking systems. Both systems are fully automatic and overall faster.

Our in-line system is a high precision placing unit, positioned behind a new or existing core cutting line. Its stacking capacity is in accordance with the cutting speed of the line. The offline E-stacker is a compact stand-alone pick and place unit. Sheets are picked from irregular stacks and automatically placed in an E-shape. In order to detect out of range tolerances the gaps between the sheets are scanned.

Your project soon?

Contact us.

-

Turn-key

solutions -

Expert in

sheet metal processing -

Member of the

Valtech Group -

Contact us

regarding your project